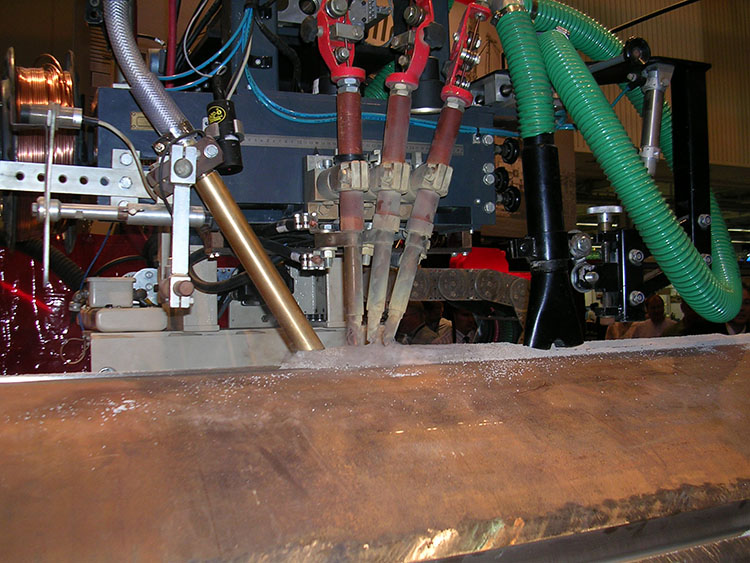

Njira yowotcherera arc ndi njira yabwino kwambiri yopangira mapaipi, zotengera zokakamiza ndi akasinja, kupanga ma track ndi zomangamanga zazikulu.Ili ndi mawonekedwe a waya wosavuta kwambiri, mawonekedwe awaya awiri, mawonekedwe awaya awiri ndi mawaya angapo.

Njira yowotcherera yomwe ili pansi pamadzi imatha kupindulitsa ogwiritsa ntchito pazinthu zambiri zowotcherera, kuyambira pakuchulukirachulukira kupita kumalo ogwirira ntchito bwino kupita kukhalidwe lokhazikika ndi zina zambiri.Zomera zopangira zitsulo zomwe zikuganiza zopanga kusintha kwa kuwotcherera kwa arc pansi pamadzi ziyenera kuganizira za mapindu ambiri omwe angapezeke panjirayi.

Chidziwitso choyambirira cha kuwotcherera arc pansi pamadzi

Njira yowotcherera ya arc ndi yoyenera pazofunikira zamafakitale zopangira mapaipi, zotengera zopondereza ndi akasinja, zomangamanga zamagalimoto, zomanga zolemetsa / kukumba.Ndi abwino kwa mafakitale omwe amafunikira zokolola zambiri, makamaka omwe amawotcherera zinthu zokhuthala kwambiri, zomwe zitha kupindula kwambiri ndi njira yowotcherera ya arc yomwe ili pansi pamadzi.

Kukwera kwake komanso kuthamanga kwaulendo kumatha kukhudza kwambiri zokolola za ogwira ntchito, kuchita bwino komanso mtengo wopangira, womwe ndi umodzi mwamaubwino ofunikira pakuwotcherera kwa arc pansi pamadzi.

Zopindulitsa zina ndi izi: ma weld okhala ndi mankhwala abwino kwambiri komanso makina amakina, mawonekedwe ochepa a arc ndi mpweya wowotcherera wocheperako, kukhazikika kwa malo ogwirira ntchito, komanso mawonekedwe abwino a weld ndi chingwe chala chala.

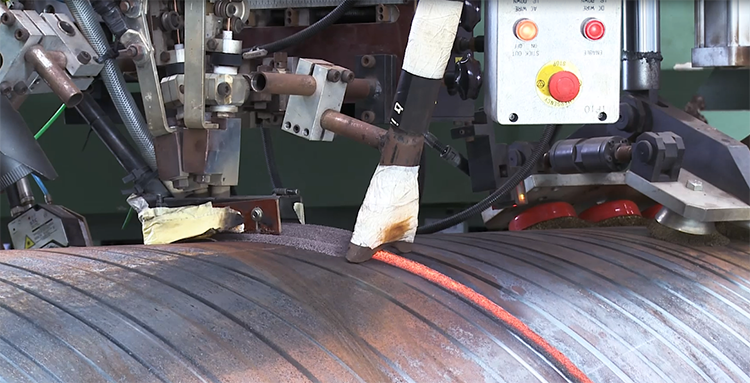

Kuwotcherera kwa arc ndi njira yodyetsera waya yomwe imagwiritsa ntchito granular flux kulekanitsa arc ndi mpweya.Monga momwe dzinalo likusonyezera, arc imakwiriridwa mu flux, kutanthauza kuti pamene magawo aikidwa, arc ndi yosaoneka ndi kutuluka kwa gawo lotsatira la flux.

Waya amadyetsedwa mosalekeza ndi nyali yoyenda motsatira weld.Kutentha kwa Arc kumasungunula gawo la waya, gawo la flux ndi zinthu zapansi kuti apange dziwe losungunuka, lomwe limakhala lopangidwa ndi weld lomwe limakutidwa ndi wosanjikiza wa slag.

Makulidwe osiyanasiyana azinthu zowotcherera ndi 1/16 "-3/4", omwe amatha kuwotcherera 100% kudzera pakuwotcherera limodzi chiphaso, ngati makulidwe a khoma sali ochepa, amatha kuwotcherera ma pass-pass, ndikuchita zoyenera. kusankhiratu chithandizo cha weld, ndikusankha kuphatikiza koyenera kwa waya.

Flux ndi kusankha waya

Kusankha kusinthasintha koyenera ndi waya kwa njira inayake yowotcherera arc yomwe ili pansi pamadzi ndikofunikira kuti mukwaniritse zotsatira zabwino kwambiri ndi njirayi.Ngakhale njira yowotcherera ya arc yokhayokha ndiyothandiza, zokolola ndi zogwira mtima zitha kuonjezedwa kutengera waya ndi kutulutsa komwe kumagwiritsidwa ntchito.

Kuthamanga sikumangoteteza dziwe la weld, komanso kumathandizira kupititsa patsogolo makina ndi zokolola za weld.Kupanga kwa flux kumakhudza kwambiri zinthu izi, zomwe zimakhudza mphamvu yakunyamula komanso kumasulidwa kwa slag.Kunyamula komwe kulipo kumatanthauza kuti kuthekera kwapamwamba kwambiri komwe kungatheke komanso mbiri ya weld yapamwamba imatha kupezeka.

Kutulutsa kwa slag kwa mtundu wina kumakhudza kusankha kwa flux chifukwa ma fluxes ena ndi oyenerana ndi mapangidwe ena owotcherera kuposa ena.

Zosankha za Flux zowotcherera arc pansi pamadzi zimaphatikizapo mitundu yogwira komanso yosalowererapo yowotcherera.Kusiyana kwakukulu ndikuti kusinthasintha kogwira kumasintha chemistry ya weld, pomwe kusalowerera ndale sikumatero.

Kuthamanga kwachangu kumadziwika ndi kuphatikiza kwa silicon ndi manganese.Zinthu izi zimathandizira kuti ma weld azitha kukhazikika pakuyika kutentha kwakukulu, amathandizira weld kukhala wosalala pakuyenda kwambiri komanso kutulutsa bwino kwa slag.

Ponseponse, kusinthasintha kwachangu kumatha kuthandizira kuchepetsa chiwopsezo chopanda kuwotcherera bwino, komanso kuyeretsa kokwera mtengo pambuyo pa weld ndikukonzanso.

Kumbukirani, komabe, kuti flux yogwira nthawi zambiri imakhala yabwino kwambiri pakuwotcherera kamodzi kapena kawiri.Miyendo yosalowerera ndale ndi yabwino kwa ma welds akuluakulu a ma pass-pass chifukwa amathandizira kupewa kupanga ma welds owopsa, osamva ming'alu.

Pali njira zambiri zamawaya zowotcherera arc pansi pamadzi, iliyonse ili ndi zabwino ndi zovuta zake.Mawaya ena amapangidwa kuti aziwotcherera potengera kutentha kwambiri, pomwe ena amapangidwa mwapadera kuti akhale ndi ma alloys omwe amathandiza kuyeretsa kuyeretsa.

Onani kuti mankhwala katundu wa waya ndi kutentha athandizira mogwirizana zingakhudze makina katundu wa weld.Kupanga kungapitirirenso kwambiri podzaza kusankha zitsulo.

Mwachitsanzo, kugwiritsa ntchito waya wachitsulo wokhala ndi kuwotcherera kwa arc pansi pamadzi kumatha kukulitsa luso loyikapo ndi 15 mpaka 30 peresenti poyerekeza ndi kugwiritsa ntchito waya wolimba, komanso kumapereka mbiri yotakata, yosazama kwambiri.

Chifukwa cha liwiro lake loyenda kwambiri, waya wachitsulo wachitsulo amachepetsanso kutentha kuti achepetse kusokonezeka kwa kuwotcherera ndi kuwotcha.Mukakayika, funsani wopanga zitsulo zodzaza kuti adziwe mawaya ndi ma flux omwe ali abwino kwambiri pakugwiritsa ntchito.

Nthawi yotumiza: Jun-27-2023