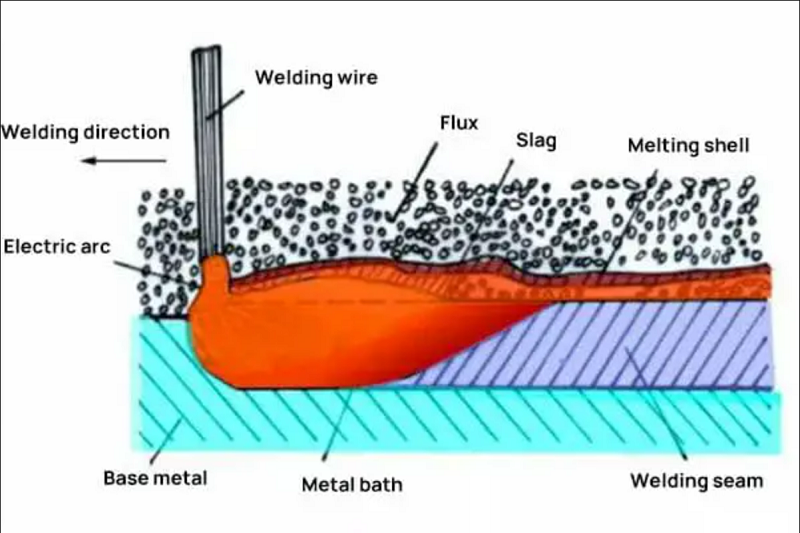

Fluxndi granular kuwotcherera chuma.Panthawi yowotcherera, imatha kusungunuka kuti ipange slag ndi gasi, zomwe zimagwira ntchito yoteteza komanso yachitsulo padziwe losungunuka.

Constituent

Flux imapangidwa ndi nsangalabwi, quartz, fluorite ndi ores ena ndi titaniyamu dioxide, mapadi ndi mankhwala ena.Flux imagwiritsidwa ntchito kwambiri pakuwotcherera arc pansi pamadzi ndi kuwotcherera kwa electroslag.Pamene ntchito kuwotcherera mitundu yonse ya zitsulo ndi sanali achitsulo zitsulo, ayenera kukhala wololera ntchito ndi lolingana kuwotcherera waya kuti kupeza wololera wokwanira.

Gulu

Pali njira zambiri zamagulu amtundu wa flux, malinga ndi kugwiritsa ntchito, njira yopangira, kupanga mankhwala, kuwotcherera ndi zitsulo zamagulu, komanso malinga ndi pH ya flux, gulu la flux granularity.Ziribe kanthu kuti ndi njira yanji yamagulu, zimangowonetsa mawonekedwe a flux kuchokera ku mbali ina, sizingaphatikizepo mawonekedwe onse a flux.Njira zomwe zimagwiritsidwa ntchito kwambiri ndi izi:

1. Kusalowerera ndale

Kuthamanga kosalowerera ndale kumatanthawuza kusinthasintha komwe sikumasintha kwambiri mankhwala azitsulo zosakanikirana ndi mankhwala a waya wowotcherera pambuyo pa kuwotcherera.Kuthamanga kosalowerera ndale kumagwiritsidwa ntchito powotcherera ma-pass-pass, makamaka kuwotcherera kwachitsulo choyambira ndi makulidwe akulu kuposa 25mm.

a.Kuthamanga kwenikweni kulibe SiO2, MnO, FeO ndi ma oxides ena.

b.Flux ilibe makutidwe ndi okosijeni pazitsulo zowotcherera kwenikweni.

c.Mukawotcherera zitsulo zokhala ndi okosijeni kwambiri, ma pores ndi ming'alu yama weld amapangidwa.

2. Kusinthasintha kwachangu

Active flux imatanthawuza kuwonjezera pang'ono kwa Mn, Si deoxidizer flux.Ikhoza kusintha kukana kwa porosity ndi crack.Active flux ili ndi izi:

a.Chifukwa cha deoxidizer, Mn ndi Si muzitsulo zosungunuka zidzasintha ndi mphamvu ya arc.Kuwonjezeka kwa Mn ndi Si kudzawonjezera mphamvu yachitsulo chosungunula ndikuchepetsa mphamvu yake.Chifukwa chake, voteji ya arc iyenera kuyendetsedwa mosamalitsa pamene kuwotcherera kwa ma multi-pass.

b.Active flux imakhala ndi kukana kwamphamvu kwa porosity.

3. Aloyi flux

Aloyi flux anawonjezera zigawo zikuluzikulu aloyi kwa kusintha kwa zinthu alloying, ambiri aloyi flux ndi sintered flux.Aloyi Flux imagwiritsidwa ntchito kwambiri pakuwotcherera chitsulo chochepa cha alloy komanso mawonekedwe osagwira ntchito.

4. Sungunulani kusinthasintha

Sungunulani flux ndi zopangira zamchere zosiyanasiyana zosakanikirana molingana ndi chiŵerengero choperekedwa, zimatenthedwa kufika madigiri oposa 1300, zimasungunuka ndi kusonkhezera mofanana, ndiyeno zitakhazikika m'madzi kuti granulate.Pambuyo kuyanika, kugaya, kuwunika, kugwiritsa ntchito phukusi.

Mtundu wa kusungunuka kwa m'nyumba kumawonetsedwa ndi "HJ".Nambala yoyamba itatha ikuwonetsa zomwe zili mu MnO, nambala yachiwiri ikuwonetsa zomwe zili mu SiO2 ndi CaF2, ndipo nambala yachitatu ikuwonetsa mitundu yosiyanasiyana yamtundu womwewo wa flux.

5. Sintering flux

Ndi youma osakaniza malinga ndi gawo anapatsidwa zosakaniza, ndiyeno kuwonjezera binder (madzi galasi) kwa chonyowa kusanganikirana, ndiyeno granulation, ndiyeno kutumizidwa ku kuyanika ng'anjo kuchiritsa, kuyanika, ndipo potsiriza sintered ndi pafupifupi 500 madigiri.

Mtundu wa sintered flux wapakhomo umayimiridwa ndi "SJ", nambala yoyamba pambuyo pake imayimira dongosolo la slag, ndipo manambala achiwiri ndi achitatu amayimira mitundu yosiyanasiyana yamtundu womwewo wa slag system.

Nthawi yotumiza: May-04-2023