The ❖ kuyanika amasewera zovuta zitsulo anachita ndi kusintha kwa thupi ndi mankhwala mu ndondomeko kuwotcherera, amene kwenikweni anagonjetsa mavuto kuwotcherera chithunzi elekitirodi, kotero ❖ kuyanika ndi chimodzi mwa zifukwa zazikulu kudziwa ubwino wa weld zitsulo.

Chophimba cha Electrode:Amatanthauza ❖ kuyanika wosanjikiza zabwino granular zakuthupi ndi osiyana thupi ndi mankhwala katundu uniformly TACHIMATA pamwamba pa kuwotcherera pachimake.

Udindo waelectrode kuwotchererazokutira:Pakuwotcherera, imapanga slag yokhala ndi malo oyenera osungunuka, kukhuthala, kachulukidwe, alkalinity ndi zinthu zina zakuthupi ndi zamankhwala, kuonetsetsa kuyaka kosasunthika kwa arc, kupangitsa kuti dontho lachitsulo lisinthike mosavuta, kulenga mlengalenga mozungulira dera la arc ndi dziwe losungunuka kuteteza. malo kuwotcherera, ndi kupeza bwino weld mapangidwe ndi ntchito.Powonjezera deoxidizer, alloying element kapena zinthu zina zachitsulo za ufa pa zokutira, zimathanso kukwaniritsa zofunikira za weld metal performance kapena kupititsa patsogolo kusungunuka kwachitsulo.

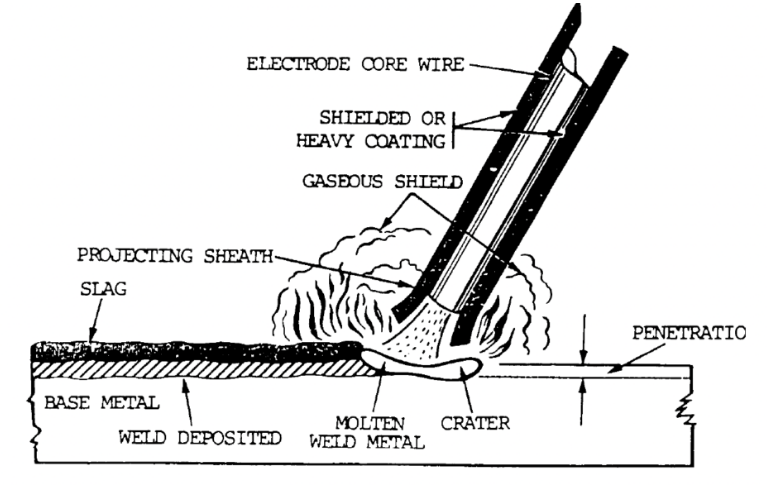

Mfundo yowotcherera arc electrode:

1. Khungu la mankhwala

2. Weld pachimake

3. Tetezani mpweya

4: nja

5. Dziwe losungunuka

6. Zida zoyambira

7. Weld

8. Kuwotcherera slag

9. Mbalame

10. Sungunulani madontho

Zopangira zosiyanasiyana molingana ndi gawo lawo pakuyika ma electrode zitha kugawidwa m'magulu awiri:

(1) Arc stabilizer

Ntchito yayikulu ndikupangitsa ma elekitirodi kukhala osavuta kuyambitsa arc ndikusunga kuyaka kosasunthika kwa arc pakuwotcherera.Monga arc stabilizer zopangira makamaka zina zomwe zimakhala ndi zinthu zochepa za ionization zomwe zimatha ionizing mosavuta, monga feldspar, sodium silicate, rutile, titanium dioxide, marble, mica, ilmenite, kuchepetsedwa ilmenite ndi zina zotero.

(2) Wopangira mafuta

Pansi pa kutentha kwa arc kuwonongeka kwa mpweya, kupanga mpweya wotetezera, kuteteza arc ndi chitsulo chosungunuka, kuteteza kulowetsedwa kwa mpweya ndi nayitrogeni mumlengalenga.Zomwe zimagwiritsidwa ntchito kwambiri popanga mpweya ndi carbonate (monga marble, dolomite, rhombic acid, barium carbonate, etc.) ndi zinthu zakuthupi (monga nkhuni ufa, wowuma, mapadi, utomoni, etc.).

(3) Deoxidizer (yomwe imadziwikanso kuti kuchepetsa wothandizira)

Mpweya wa okosijeni mu zitsulo zowotcherera ukhoza kuchepetsedwa ndipo magwiridwe antchito a chitsulo chowotcherera amatha kupitilizidwa ndi zitsulo zamakina munjira yowotcherera.Deoxidizer imakhala ndi zinthu za aloyi yachitsulo ndi ufa wachitsulo womwe umalumikizana kwambiri ndi mpweya.Zomwe zimagwiritsidwa ntchito kwambiri ndi deoxidizer ndi ferromanganese, ferrosilicon, ferrotitanium, ferroaluminium, silicon calcium alloy, etc.

(4) Pulasitiki

Ndi ntchito yaikulu ndi kusintha plasticity, elasticity ndi fluidity m`kati ma elekitirodi mbamuikha ❖ kuyanika , kupititsa patsogolo ❖ kuyanika khalidwe elekitirodi, kuti yosalala pamwamba ❖ kuyanika ma elekitirodi si kusweka.Nthawi zambiri kusankha elasticity, poterera kapena kuyamwa pambuyo zina kukula makhalidwe a zipangizo, monga mica, matope woyera, titaniyamu dioxide, talc, madzi olimba galasi, mapadi, etc.

(5) Aloyi wothandizira

Amagwiritsidwa ntchito kubwezera kuyaka kwa zinthu zowotcherera pakuwotcherera ndikusamutsa zinthu zopangira ma weld, kuti zitsimikizire kapangidwe kake ndi katundu wa chitsulo chowotcherera.Malinga ndi kufunika kusankha zosiyanasiyana ferroalloys (monga ferromanganese, ferrosilicon, ferrochrome, chitsulo ndi chitsulo, ferric vanadium, ferric niobium, ferric boron, osowa lapansi ferrosilicon, etc.) kapena zitsulo koyera (monga manganese zitsulo, chromium zitsulo , faifi tambala, tungsten ufa, etc.).

(6) Wopanga masilagi

kuwotcherera akhoza kupanga ena thupi ndi mankhwala katundu wa slag wosungunula, kuteteza kuwotcherera droplet ndi chitsulo chosungunuka dziwe, kusintha kuwotcherera mapangidwe, monga slagging wothandizila wa zopangira ndi nsangalabwi, fluorite, dolomite, magnesia, feldspar, matope woyera, mica, khwatsi. , rutile, titanium dioxide, ilmenite, etc.

(7) Binda

Chophimbacho chimamangirizidwa mwamphamvu pazitsulo zowotcherera, ndipo zokutira za electrode zimakhala ndi mphamvu zina pambuyo poyanika.Mu ndondomeko kuwotcherera zitsulo, palibe zotsatira zoipa pa weld dziwe ndi weld zitsulo.Zomwe zimagwiritsidwa ntchito kwambiri ndi sodium silicate (potaziyamu, sodium ndi sodium silicate) ndi phenolic resin, chingamu, etc.

Nthawi yotumiza: May-04-2023