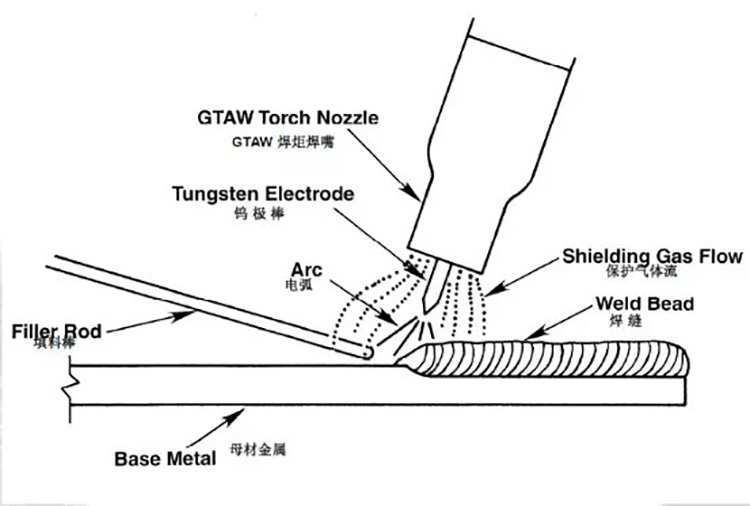

Kuwotcherera kwa Argon tungsten arc kumagwiritsa ntchito argon ngati mpweya wotchingira kutentha ndikusungunula zinthu zowotcherera zokha (zimasungunukanso pamene zitsulo zodzaza zimawonjezeredwa) pogwiritsa ntchito arc yomwe imapangidwa pakati pa tungsten elekitirodi ndi thupi la weld, kenako ndikupanga kuwotcherera. wa weld metal Way.Thetungsten electrode,dziwe la weld, arc ndi malo olowa msoko amatenthedwa ndi arc amatetezedwa ku kuipitsidwa kwamlengalenga ndi kutuluka kwa argon.

Panthawi yowotcherera argon arc, malo ogwirizana a nyali, zitsulo zodzaza ndi zowotcherera zikuwonetsedwa pachithunzichi: kutalika kwa arc nthawi zambiri kumakhala 1 ~ 1.5 m'mimba mwake mwa electrode ya tungsten.Kuwotcherera kukayimitsidwa, zitsulo zodzaza zimachotsedwa ku dziwe losungunuka (zitsulo zodzaza zimawonjezeredwa malinga ndi makulidwe a weldment), ndipo mapeto otentha amafunikabe kukhala pansi pa chitetezo cha argon kuti ateteze oxidation yake. .

1. Tochi yowotcherera (muuni)

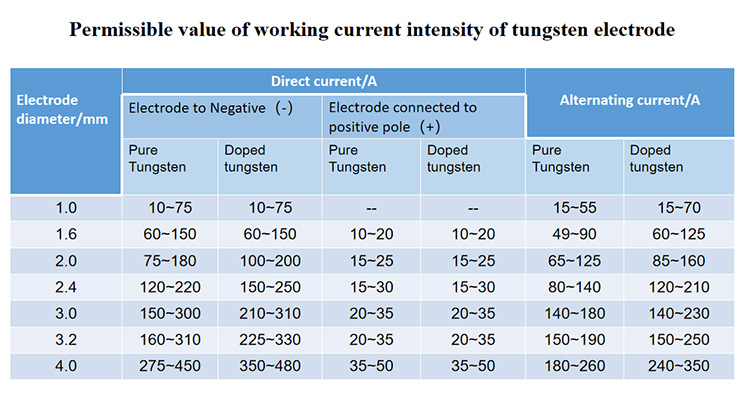

Kuphatikiza pa kumangitsa ma elekitirodi a tungsten ndikupereka magetsi, nyali yowotcherera ya argon tungsten arc (yomwe imadziwikanso kuti tochi yowotcherera) iyeneranso kupopera mpweya wotchinga.Mfuti zowotcherera zamtundu wapamwamba zimayenera kugwiritsa ntchito mfuti zowotcherera zotenthetsera madzi kuti ziwotchere nthawi yayitali.Chifukwa chake, kugwiritsa ntchito moyenera ndi kuteteza nyali yowotcherera ndikofunikira kwambiri.Tungsten electrode load current (A) ikuwonetsedwa mu tebulo ili m'munsimu.

2. Njira ya gasi

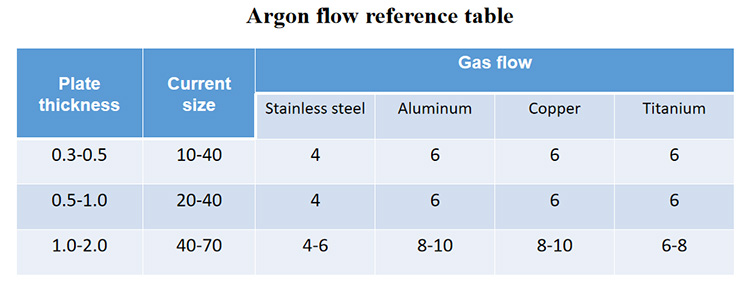

Njira ya gasi imapangidwa ndi argon cylinder pressure reduction valve, flow mita, hose ndi electromagnetic gas valve (mkati mwa makina owotcherera).Valavu yochepetsera mphamvu imagwiritsidwa ntchito kuchepetsa kupanikizika ndikusintha kupanikizika kwa mpweya woteteza.Flowmeter imagwiritsidwa ntchito kuwongolera ndikusintha kayendedwe ka gasi woteteza.Argon arc kuwotcherera makina nthawi zambiri ntchito ophatikizana decompression flowmeter, amene ndi yabwino ndi odalirika ntchito.

Pa kuwotcherera kwa argon arc, chofunikira pakuyera kwa gasi wa argon ndikuti chitsulo chosapanga dzimbiri cha chromium-nickel chiyenera kukhala ≥99.7%, ndipo chitsulo chosakanizira chiyenera kukhala ≥99.98%.

(1) Argon ndi mpweya wa inert, ndipo sikophweka kuchitapo kanthu ndi zipangizo zina zachitsulo ndi mpweya.Komanso, chifukwa cha kuzizira kwa kayendedwe ka mpweya, malo okhudzidwa ndi kutentha kwa weld ndi ochepa ndipo kusinthika kwa weldment kumakhala kochepa.Ndiwowotchera bwino kwambiri wotchingira argon tungsten arc.

(2) Argon makamaka ntchito kuteteza bwino dziwe losungunuka, kuteteza mpweya kukokera dziwe losungunuka ndi chifukwa makutidwe ndi okosijeni pa ndondomeko kuwotcherera, ndipo nthawi yomweyo bwino kudzipatula mpweya m'dera weld, kotero kuti weld dera. kutetezedwa ndi kuwotcherera ntchito bwino.

(3) Njira yosinthira imatsimikiziridwa molingana ndi zitsulo zomwe zimayenera kuwotcherera, kukula kwamakono, ndi njira yowotcherera: kuwonjezereka kwamakono, kumapangitsanso mpweya wotetezera.Pazinthu zogwira ntchito, mpweya woteteza uyenera kulimbikitsidwa kuti uwonjezere kuthamanga.

3. Mafotokozedwe magawo

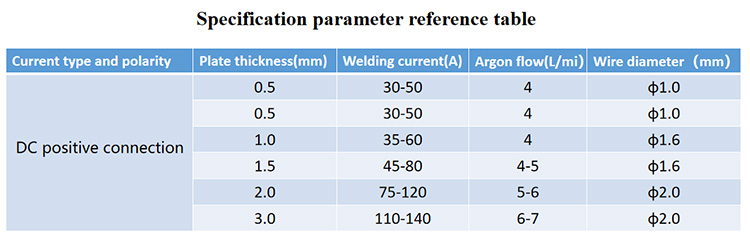

Muyezo magawo a argon tungsten arc kuwotcherera makamaka panopa, voteji, kuwotcherera liwiro, ndi argon mpweya kuyenda, ndipo mfundo zawo zimagwirizana ndi mtundu wa zinthu kuti welded, mbale makulidwe ndi mtundu olowa.

Zotsalira zotsalira monga kutalika kwa ma elekitirodi a tungsten otuluka pamphuno nthawi zambiri amakhala 1-2 m'mimba mwake mwa ma elekitirodi a tungsten, mtunda wa pakati pa tungsten electrode ndi weldment (utali wa arc) nthawi zambiri umakhala nthawi 1.5 m'mimba mwake mwa tungsten. electrode, ndipo kukula kwa nozzle kumatsimikiziridwa pambuyo poti mtengo wa kuwotcherera watsimikiziridwa.Sankhani kachiwiri.

General Stainless steel argon arc kuwotcherera kwachitsulo ndi motere:

4. Kuyeretsa pamaso kuwotcherera

Tungsten argon arc kuwotcherera ndi tcheru kwambiri kuipitsidwa kwa weldment ndi filler zitsulo pamwamba, kotero mafuta, ❖ kuyanika, lubricant ndi okusayidi filimu pamwamba pa kuwotcherera ayenera kuchotsedwa pamaso kuwotcherera.

5. Ukadaulo wachitetezo

Oyendetsa argon tungsten arc welding ayenera kuvala masks akumutu, magolovesi, zovala zantchito, ndi nsapato zogwirira ntchito kuti apewe kuyaka kwa ultraviolet ndi infrared mu arc.Makina owotcherera a Steyr tungsten argon arc ali ndi zoyambira zoyambira pafupipafupi.Ngakhale magetsi otsika kwambiri omwe ali ndi magetsi apamwamba kwambiri sangadodometse wogwiritsa ntchito, pamene ntchito yotsekemera imakhala yosauka, magetsi othamanga kwambiri amawotcha khungu la dzanja la wogwiritsa ntchito, ndipo n'zovuta kuchiza, choncho ntchito yotsekemera chogwirira kuwotcherera ayenera kufufuzidwa pafupipafupi.Pa kuwotcherera kwa argon tungsten arc, mpweya wabwino m'malo owotcherera uyenera kukulitsidwa.

Zindikirani: Chinthu chachikulu ndicho kukhala waluso komanso waluso.Makulidwe a bolodi, nthawi yakudina, ndi pano zonse zimagwirizana, ndipo ziyenera kugwirizana wina ndi mnzake.

Pamene kuwotcherera, musaloze nsonga ya singano pa malo owotcherera pa chiyambi, ndi kumenya opanda kanthu poyamba kutulutsa mpweya mu chitoliro, kotero kuti kuwotcherera si kuwotcherera ndipo sipadzakhala mawanga akuda.Masekondi angapo, motere, chitsulo chosapanga dzimbiri chimatetezedwa ndi mpweya wa argon panthawi yozizira, kotero sichidzakhala chakuda, ndipo ngakhale madzi otsuka ndi pepala lopukuta zimasungidwa.Izi zitha kugwiritsidwa ntchito kuwotcherera malo.Ngati mukoka kuwotcherera kwa mtunda wautali, palibe njira.The bolodi ndithu kusintha mtundu.Muyenera kuyembekezera kupukuta ndi kuyeretsa.

Nthawi yotumiza: May-16-2023