The kuwotcherera magawo ma elekitirodi arc kuwotcherera makamaka ma elekitirodi awiri, kuwotcherera panopa, arc voteji, chiwerengero cha zigawo kuwotcherera, mphamvu gwero mtundu ndi polarity, etc.

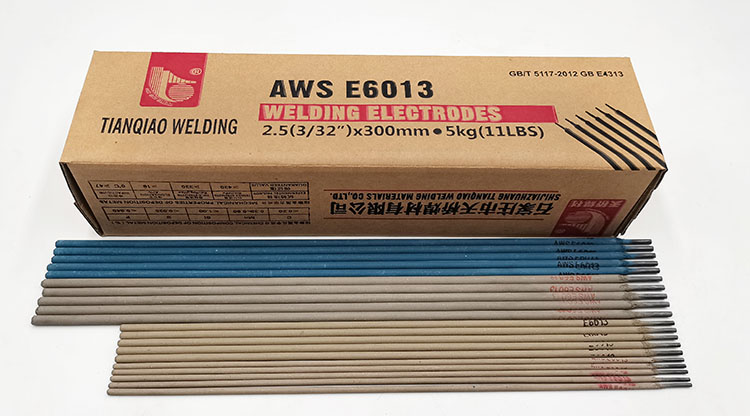

1. Kusankhidwa kwa electrode diameter

Kusankhidwa kwa ma elekitirodi awiri makamaka zimadalira zinthu monga makulidwe a weldment, mtundu wa olowa, udindo wa weld ndi mlingo kuwotcherera.Poganizira kuti sizikhudza mtundu wa kuwotcherera, kuti muwonjezere zokolola zantchito, nthawi zambiri amasankha ma elekitirodi okulirapo.

Pazigawo zowotcherera zokhala ndi makulidwe okulirapo, ma elekitirodi okulirapo ayenera kugwiritsidwa ntchito.Pakuti kuwotcherera lathyathyathya, awiri a elekitirodi ntchito akhoza kukhala lalikulu;kwa kuwotcherera ofukula, m'mimba mwake wa elekitirodi ntchito zosaposa 5 mm;kwa kuwotcherera yopingasa ndi kuwotcherera pamwamba, ndi awiri a elekitirodi ntchito zambiri zosaposa 4 mm.Pankhani ya kuwotcherera kwamitundu ingapo yokhala ndi ma groove ofanana, kuti mupewe zolakwika zolowera mosagwirizana, ma elekitirodi a mainchesi a 3.2 mm ayenera kugwiritsidwa ntchito pakuwotcherera koyamba.Nthawi zonse, ma electrode awiri amatha kusankhidwa malinga ndi makulidwe a weldment (monga momwe tafotokozera mu Table TQ-1).

| Gulu: TQ-1 | Mgwirizano wa ma electrode awiri ndi makulidwe | |||

| makulidwe a weldment (mm) | ≤2 | 3-4 | 5-12 | > 12 |

| Electrode diameter (mm) | 2 | 3.2 | 4-5 | ≥5 |

2. Kusankhidwa kwa kuwotcherera panopa

Kukula kwa kuwotcherera pakali pano kumakhudza kwambiri khalidwe la kuwotcherera ndi zokolola.Ngati panopa ndi yaying'ono kwambiri, arc ndi yosakhazikika, ndipo n'zosavuta kuyambitsa zolakwika monga kuphatikizidwa kwa slag ndi kulowa kosakwanira, ndipo zokolola zimakhala zochepa;ngati madziwa ndi aakulu kwambiri, zolakwika monga kung'ambika ndi kuwotcha zimatha kuchitika, ndipo sipatsira imawonjezeka.

Chifukwa chake, pakuwotcherera ndi kuwotcherera ma electrode arc, kuwotcherera kwapano kuyenera kukhala koyenera.Kukula kwa kuwotcherera pakali pano kumatsimikiziridwa ndi zinthu monga mtundu wa elekitirodi, ma elekitirodi m'mimba mwake, makulidwe a weldment, mtundu wolumikizirana, malo otchingira malo ndi mulingo wowotcherera, womwe zinthu zofunika kwambiri ndi m'mimba mwake wa elekitirodi ndi malo owotcherera.Mukamagwiritsa ntchito maelekitirodi achitsulo, mgwirizano pakati pa kuwotcherera pano ndi m'mimba mwake wa electrode ukhoza kusankhidwa ndi njira yoyeserera: I = kd

Mu chilinganizo, ine ndikuimira kuwotcherera panopa (A);imayimira kukula kwa electrode (mm);

k imayimira coefficient yokhudzana ndi kukula kwa electrode (onani Table TQ-2 kuti musankhe).

| Gulu: TQ-2 | kmtengo wamitundu yosiyanasiyana ya electrode | |||

| d/mm | 1.6 | 2-2.5 | 3.2 | 4-6 |

| k | 15-25 | 20-30 | 30-40 | 40-50 |

Kuonjezera apo, malo a weld ndi osiyana, ndipo kukula kwa kuwotcherera panopa kumasiyananso.Nthawi zambiri, kuwotcherera kwa ofukula kuyenera kukhala 15% ~ 20% kutsika kuposa komwe kumawotcherera lathyathyathya;kuwotcherera yopingasa ndi kuwotcherera pamwamba ndi 10% ~ 15% m'munsi kusiyana ndi kuwotcherera lathyathyathya.Kuchuluka kwa kuwotcherera ndi kwakukulu, ndipo malire apamwamba a panopa amatengedwa nthawi zambiri.

Ma elekitirodi azitsulo a aloyi okhala ndi zinthu zambiri zophatikizika amakhala ndi kukana kwamagetsi kwambiri, kuchuluka kwamafuta owonjezera, kuchuluka kwamagetsi panthawi yowotcherera, ndipo ma elekitirodi amatha kukhala ofiira, zomwe zimapangitsa kuti zokutira zigwe nthawi isanakwane, zomwe zimakhudza mtundu wazowotcherera, ndipo ma alloyine amawotchedwa. zambiri, kotero kuwotcherera Pakali pano kumachepetsedwa moyenerera.

3. Kusankhidwa kwa arc voltage

Mphamvu ya arc imatsimikiziridwa ndi kutalika kwa arc.Ngati arc ndi yayitali, mphamvu ya arc ndiyokwera;ngati arc ili yochepa, mphamvu ya arc ndi yochepa.Powotcherera, ngati arc ndi yayitali kwambiri, arc idzawotcha mosakhazikika, spatter idzawonjezeka, kulowa kumachepa, ndipo mpweya wakunja udzalowa anthu mosavuta, zomwe zimayambitsa zolakwika monga pores.Choncho, kutalika kwa arc kumafunika kukhala kochepa kapena kofanana ndi kukula kwa electrode, ndiko kuti, kuwotcherera kwa arc.Mukamagwiritsa ntchito electrode ya asidi pakuwotcherera, kuti mutenthetse gawolo kuti liwotchedwe kapena kuchepetsa kutentha kwa dziwe losungunuka, nthawi zina arc imatambasulidwa pang'ono pakuwotcherera, yomwe imatchedwa kuwotcherera kwakutali.

4. Kusankhidwa kwa chiwerengero cha zigawo zowotcherera

Mipikisano wosanjikiza kuwotcherera nthawi zambiri ntchito kuwotcherera arc ya sing'anga ndi wandiweyani kuwotcherera.Zigawo zambiri ndizopindulitsa kuwongolera pulasitiki ndi kulimba kwa weld, makamaka pamakona ozizira opindika.Komabe, ndikofunikira kuti tipewe zotsatira zoyipa za kutenthedwa kwa mgwirizano ndikukulitsa malo omwe amakhudzidwa ndi kutentha.Kuphatikiza apo, kuchuluka kwa zigawo kumawonjezera kusinthika kwa weldment.Chifukwa chake, iyenera kutsimikiziridwa ndi kulingalira kokwanira.

5. Kusankhidwa kwa mtundu wamagetsi ndi polarity

Magetsi a DC ali ndi arc yokhazikika, spatter yaying'ono komanso mtundu wabwino wowotcherera.Nthawi zambiri amagwiritsidwa ntchito kuwotcherera zinthu zofunika zowotcherera kapena mbale zokhuthala zokhala ndi zida zazikulu zolimba.

Nthawi zina, muyenera kuganizira kaye kugwiritsa ntchito makina owotcherera a AC, chifukwa makina owotcherera a AC ali ndi mawonekedwe osavuta, otsika mtengo, osavuta kugwiritsa ntchito ndikuwongolera kuposa makina owotcherera a DC.Kusankhidwa kwa polarity kumachokera ku chikhalidwe cha electrode ndi makhalidwe a kuwotcherera.Kutentha kwa anode mu arc ndikokwera kuposa kutentha kwa cathode, ndipo polarities zosiyanasiyana zimagwiritsidwa ntchito powotcherera ma welds osiyanasiyana.

Nthawi yotumiza: Sep-30-2021