Palibe kusiyana pakati pa kuwotcherera kwathunthu kwa argon arc ndi kuwotcherera kwa argon arc.Kuwotcherera kwa argon arc ndikoyenera kwa mapaipi ang'onoang'ono okhala ndi mipanda (nthawi zambiri DN60 ndi pansi, makulidwe a khoma 4mm), cholinga chake ndikuwonetsetsa kuti mizu yowotcherera ndi mawonekedwe ake.

Pamene makulidwe a chitoliro ndi aakulu ndipo makulidwe a khoma ndi wandiweyani, kuwotcherera kwa argon arc kuyenera kugwiritsidwa ntchito ngati maziko ndi kuwotcherera kwamanja kuphimba pamwamba.Cholinga cha kuwotcherera pamanja ndikuwonetsetsa kuti mawonekedwe a chitoliro chachikulu ndi kuwotcherera pamanja, ndipo magwiridwe antchito ndi apamwamba kuposa kuwotcherera kwa argon arc.otsika kuposa kuwotcherera argon arc.

The argon arc kuwotcherera pansi kuwotcherera ndondomeko ntchito kuwotcherera makoma boiler madzi, superheaters, economizers, etc. Ubwino wa olowa ndi zabwino kwambiri, ndi giredi weld ali pamwamba Class II pambuyo radiographic anayendera.

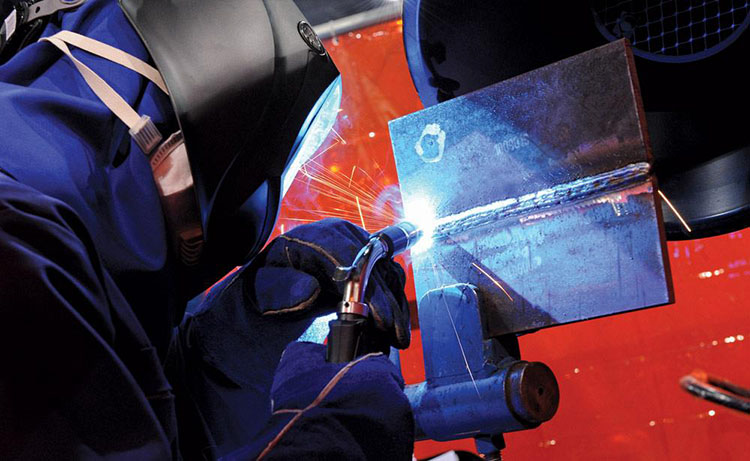

Ubwino wa kuwotcherera argon arc

(1) wabwino

Malingana ngati waya wowotcherera woyenera, magawo a ndondomeko yowotcherera ndi chitetezo chabwino cha gasi amasankhidwa, muzu ukhoza kulowa bwino, ndipo kulowa kwake kumakhala kofanana, ndipo pamwamba pake ndi yosalala komanso yaudongo.Palibe zolakwika monga ma weld tokhala, kulowa kosakwanira, kukhumudwa, pores ndi slag inclusions zomwe zimakhala zosavuta kuchitika panthawi yowotcherera arc ndi ma electrode ambiri.

(2) Kuchita bwino kwambiri

Mugawo loyamba la kuwotcherera kwa payipi, kuwotcherera kwa argon arc ndi kuwotcherera kwa arc mosalekeza.The electrode arc kuwotcherera ndi wosweka arc kuwotcherera, kotero pamanja argon arc kuwotcherera akhoza kuwonjezera dzuwa ndi 2 mpaka 4 nthawi.Popeza kuwotcherera argon arc sikutulutsa kuwotcherera slag, palibe chifukwa chotsuka slag ndikukonza mkanda wowotcherera, ndipo liwiro lidzakula mwachangu.Mu wachiwiri wosanjikiza wa arc kuwotcherera chivundikiro pamwamba, yosalala ndi yaudongo argon Arc kuwotcherera pansi wosanjikiza ndi opindulitsa kwa Arc kuwotcherera chivundikiro pamwamba, amene angatsimikizire maphatikizidwe wabwino pakati pa zigawo, makamaka kuwotcherera ang'onoang'ono mapaipi awiri, dzuwa kwambiri. kwambiri.

(3) Zosavuta kuzidziwa

Kuwotcherera kwa mizu ya kuwotcherera kwa arc kuyenera kuchitidwa ndi odziwa ntchito komanso aluso kwambiri.Kuwotcherera kwa argon arc pamanja kumagwiritsidwa ntchito pothandizira, ndipo ogwira ntchito omwe nthawi zambiri amagwira ntchito yowotcherera amatha kuidziwa kwakanthawi kochepa.

(4) Kupindika pang’ono

Malo omwe amakhudzidwa ndi kutentha ndi ochepa kwambiri panthawi yowotcherera argon arc, kotero kuti kusinthika kwa mgwirizano wowotcherera kumakhala kochepa ndipo kupanikizika kotsalira kumakhala kochepa.

Chiyambi cha ndondomeko

(1) Chitsanzo chowotcherera

The economizer, evaporator chubu mtolo, madzi khoma ndi otsika kutentha superheater amapangidwa ndi No. 20 zitsulo, ndi mkulu kutentha chubu ndi 12Cr1MoV.

(2) Kukonzekera musanawotchere

Pamaso kuwotcherera, chitoliro pakamwa ayenera beveled pa 30°, ndipo mtundu wachitsulo uyenera kupukutidwa mkati mwa 15mm mkati ndi kunja kwa chitoliro.Kusiyana pakati pa zitoliro ndi 1-3mm.Pamene kusiyana kwenikweni ndi lalikulu kwambiri, m'pofunika surfacing kusintha wosanjikiza pa mbali ya chitoliro poyambira choyamba.Khazikitsani malo osakhalitsa amphepo ndikuwongolera liwiro la mphepo pamalo opangira kuwotcherera, chifukwa liwiro la mphepo limaposa mtunda wina, ndipo mabowo amapangidwa mosavuta.

(3) Ntchito

Gwiritsani ntchito makina owotcherera a tungsten argon arc, makina owotcherera omwewo amakhala ndi chipangizo choyatsira ma arc othamanga kwambiri, ndipo kuyatsa kwa arc kumatha kugwiritsidwa ntchito.Kuzimitsa kwa Arc ndikosiyana ndi kuwotcherera kwa electrode arc.Ngati arc yazimitsidwa mwachangu kwambiri, ming'alu ya arc crater ndiyosavuta kuchitika.Choncho, pogwira ntchito, dziwe losungunuka liyenera kutsogoleredwa kumphepete kapena kuzitsulo zozama kwambiri, kenako pang'onopang'ono muchepetse dziwe losungunuka kuti lizimitse pang'onopang'ono arc, ndipo potsiriza kutseka arc.Gasi woteteza.

Kwa mapaipi achitsulo a 20 okhala ndi makulidwe a khoma la 3 ~ 4mm, zinthu zodzaza zimatha kukhala TIGJ50 (ya 12Cr1MoV, 08CrMoV ingagwiritsidwe ntchito), kutalika kwa ndodo ya tungsten ndi 2mm, kuwotcherera pano ndi 75 ~ 100A, arc voteji ndi 12 ~ 14V, ndi kuthamanga kwa mpweya wotchinga ndi 8 ~ 10L / min, mtundu wa magetsi ndi DC positive kugwirizana.

Chifukwa chomwe kuwotcherera kwa argon arc kumatha kugwiritsidwa ntchito kwambiri makamaka chifukwa cha zabwino zotsatirazi.

1. Kutetezedwa kwa Argon kumatha kudzipatula ku zotsatira zoyipa za okosijeni, nayitrogeni, haidrojeni, ndi zina zotere mumlengalenga pa arc ndi dziwe losungunuka, kuchepetsa kutayika koyaka kwa zinthu za aloyi, ndikupeza zolumikizana zowuma, zopanda spatter, zapamwamba kwambiri;

2. Kuwotcherera kwa arc kwa argon arc welding ndikokhazikika, kutentha kumakhala kokhazikika, kutentha kwa arc column ndikwapamwamba, kupanga kuwotcherera ndikokwera kwambiri, malo omwe amakhudzidwa ndi kutentha ndi opapatiza, komanso kupsinjika, kupunduka ndi chizolowezi chong'ambika cha welded. mbali ndi zazing'ono;

3. Argon arc kuwotcherera ndi kuwotcherera kwa arc, komwe kuli kosavuta kugwira ntchito ndi kuyang'anitsitsa;

4. Kutayika kwa electrode kumakhala kochepa, kutalika kwa arc ndikosavuta kusamalira, ndipo palibe kusinthasintha kapena zokutira wosanjikiza panthawi yowotcherera, kotero ndikosavuta kuzindikira makina ndi automation;

5. Argon arc kuwotcherera akhoza kuwotcherera pafupifupi zitsulo, makamaka zitsulo refractory ndi mosavuta oxidized zitsulo, monga magnesium, titaniyamu, molybdenum, zirconium, zotayidwa, etc. ndi kabisidwe awo;

6. Sili malire ndi udindo wa weldment, ndipo akhoza welded mu maudindo onse.

Zoyipa zazikulu:

1. Chifukwa cha dera lalikulu lomwe limakhudzidwa ndi kutentha kwa argon arc kuwotcherera, ntchito yogwiritsira ntchito nthawi zambiri imayambitsa kusinthika, kuuma kwakukulu, matuza, kutsekemera kwapafupi, kusweka, pinholes, kuvala, zokopa, zochepetsera, kapena kusakwanira kugwirizanitsa mphamvu ndi kupsyinjika kwamkati pambuyo pokonza.zolakwika monga kuwonongeka.Makamaka pokonza zolakwika zazing'ono zamabizinesi ang'onoang'ono, zimawonekera pamtunda.Pankhani yokonza zolakwika za ma castings olondola, makina owotcherera ozizira angagwiritsidwe ntchito m'malo mwa kuwotcherera kwa argon arc.Chifukwa cha kutentha kwakung'ono kwa makina ozizira owotcherera, zofooka za kuwotcherera kwa argon arc zimagonjetsedwa bwino, ndipo zovuta zokonza zoponyera mwatsatanetsatane zimapangidwira.

2. Kuwotcherera kwa Argon arc kumawononga kwambiri thupi la munthu kuposa kuwotcherera arc electrode.Kachulukidwe kakachulukidwe ka argon arc welding ndi wokwera, ndipo kuwala komwe kumatulutsa kumakhala kolimba.Ma radiation a ultraviolet opangidwa ndi arc yake ndi pafupifupi a electrode arc welding wamba.Nthawi 5 mpaka 30, ndipo kuwala kwa infuraredi kumakhala pafupifupi 1 mpaka 1.5 nthawi ya electrode arc kuwotcherera.Zinthu za ozone zomwe zimapangidwa panthawi yowotcherera ndizokwera kwambiri.Choncho, yesetsani kusankha malo okhala ndi mpweya wabwino kuti mumangidwe, apo ayi zidzavulaza kwambiri thupi.

3. Pazitsulo zokhala ndi malo otsika osungunuka komanso kutuluka mosavuta (monga lead, malata, zinki), kuwotcherera kumakhala kovuta kwambiri.

Nthawi yotumiza: Aug-16-2023