Pali zovuta zina zowotcherera zitsulo zomwe zimalepheretsa kukula kwake, monga kapangidwe kake ndi magwiridwe antchito a zitsulo zosakanikirana.Kuwonongeka kwakukulu kwa kapangidwe kazitsulo kosiyana kamene kamachitika kumachitika m'malo ophatikizika.Chifukwa cha mawonekedwe osiyanasiyana a crystallization a welds mu gawo lililonse pafupi ndi malo ophatikizika, Ndikosavuta kupanga wosanjikiza wosinthika ndikuchita bwino komanso kusintha kwamapangidwe.

Kuonjezera apo, chifukwa cha nthawi yayitali pa kutentha kwakukulu, kufalikira kwa dera lino kudzawonjezeka, zomwe zidzawonjezera kusagwirizana kwachitsulo.Komanso, pamene zitsulo zosiyana ndi welded kapena pambuyo kutentha mankhwala kapena mkulu-kutentha ntchito pambuyo kuwotcherera, nthawi zambiri amapezeka kuti mpweya pa otsika aloyi mbali "kusamukira" kudutsa malire weld ku weld mkulu-aloyi, kupanga decarburization zigawo pa. mbali zonse ziwiri za mzere wophatikizika.Ndipo carburization wosanjikiza, zitsulo m'munsi amapanga decarburization wosanjikiza mbali otsika aloyi, ndi carburization wosanjikiza mawonekedwe pa mkulu aloyi weld mbali.

Zopinga ndi zolepheretsa kugwiritsa ntchito ndi chitukuko cha zitsulo zosiyana zimawonekera makamaka muzinthu izi:

1. Pa kutentha kwa firiji, zida zamakina (monga kulimba, kugunda, kupindika, ndi zina zambiri) za malo olumikizirana olowa azitsulo zosiyana nthawi zambiri zimakhala zabwinoko kuposa zazitsulo zoyambira kuti ziwotchedwe.Komabe, pa kutentha kwakukulu kapena pambuyo pogwira ntchito kwa nthawi yaitali pa kutentha kwakukulu, ntchito ya malo olowa nawo imakhala yotsika kuposa yazitsulo zoyambira.zakuthupi.

2. Pali martensite kusintha zone pakati pa austenite weld ndi pearlite maziko zitsulo.Chigawochi chimakhala cholimba chochepa ndipo ndi cholimba cholimba kwambiri.Ndilonso gawo lofooka lomwe limayambitsa kulephera kwa gawo ndi kuwonongeka.Idzachepetsa kapangidwe ka welded.kudalirika kwa ntchito.

3. Kusamuka kwa mpweya panthawi ya chithandizo cha kutentha kwa pambuyo pa weld kapena ntchito yotentha kwambiri kumapangitsa kuti pakhale mapangidwe a carburized ndi zigawo za decarburized mbali zonse za mzere wosakanikirana.Nthawi zambiri akukhulupirira kuti kuchepetsedwa kwa kaboni mu gawo la decarburized kumabweretsa kusintha kwakukulu (nthawi zambiri kuwonongeka) pamapangidwe ndi magwiridwe antchito amderalo, zomwe zimapangitsa kuti derali likhale lovuta kwambiri panthawi yautumiki.Magawo olephera a mapaipi ambiri otentha kwambiri omwe amagwira ntchito kapena akuyesedwa amakhazikika pagawo la decarburization.

4. Kulephera kumakhudzana ndi zinthu monga nthawi, kutentha ndi kusinthana maganizo.

5. Chithandizo cha kutentha kwapambuyo-weld sichingathe kuthetsa kugawanika kwachisokonezo chotsalira m'dera lolumikizana.

6. Inhomogeneity ya mankhwala zikuchokera.

Pamene zitsulo zosiyana zimawotcherera, popeza zitsulo kumbali zonse ziwiri za weld ndi aloyi zikuchokera ku weld ndizosiyana kwambiri, panthawi yowotcherera, zitsulo zoyambira ndi zowotcherera zidzasungunuka ndikusakanikirana.Kufanana kwa kusakaniza kudzasintha ndi kusintha kwa njira yowotcherera.Kusintha, ndi kusakaniza kufanana kumasiyananso kwambiri pa malo osiyana a olowa welded, zomwe zimabweretsa inhomogeneity wa mankhwala zikuchokera welded olowa.

7. Inhomogeneity ya kapangidwe ka metallographic.

Chifukwa cha kusagwirizana kwa mankhwala ophatikizana owotcherera, atatha kukumana ndi kutentha kwa kutentha, mapangidwe osiyanasiyana amawoneka m'dera lililonse la olowa, ndipo machitidwe ovuta kwambiri a bungwe nthawi zambiri amawoneka m'madera ena.

8. Kusiya kugwira ntchito.

Kusiyana kwa mankhwala zikuchokera ndi metallographic kapangidwe ka olowa olowa zimabweretsa zosiyanasiyana mawotchi zimatha welded mfundo.Mphamvu, kuuma, pulasitiki, kulimba, katundu wokhudzidwa, kutentha kwapamwamba, ndi kukhazikika kwa madera osiyanasiyana ophatikizana ndi welded ndizosiyana kwambiri.Inhomogeneity yofunikayi imapangitsa kuti madera osiyanasiyana a olowa amachitidwe mosiyana kwambiri pamikhalidwe yomweyi, ndi malo ofooka ndi madera olimbikitsidwa akuwonekera.Makamaka pa kutentha kwambiri, zolumikizira zitsulo zosakanikirana zimagwira ntchito panthawi yantchito.Kulephera koyambirira kumachitika nthawi zambiri.

Makhalidwe a njira zowotcherera zosiyanasiyana powotcherera zitsulo zosiyana

Njira zambiri zowotcherera zitha kugwiritsidwa ntchito powotcherera zitsulo zofananira, koma posankha njira zowotcherera ndikupangira miyeso yazitsulo, ziyenera kuganiziridwabe.Malinga ndi zofunika zosiyanasiyana za zitsulo m'munsi ndi mfundo welded, kuwotcherera maphatikizidwe, kuwotcherera kuthamanga ndi njira zina kuwotcherera onse ntchito zosiyanasiyana zitsulo kuwotcherera, koma aliyense ali ubwino wake ndi kuipa.

1. Kuwotcherera

Njira yowotcherera yomwe imagwiritsidwa ntchito kwambiri pakuwotcherera zitsulo zosiyanasiyana ndi ma elekitirodi arc kuwotcherera, kuwotcherera arc pansi pamadzi, kuwotcherera kwa gasi, kuwotcherera kwa electroslag, kuwotcherera kwa plasma arc, kuwotcherera kwa elekitironi, kuwotcherera kwa laser, ndi zina zambiri. Chiŵerengero kapena kulamulira kuchuluka kwa kusungunuka kwa zipangizo zosiyanasiyana zazitsulo, kuwotcherera kwa ma elekitironi, kuwotcherera laser, kuwotcherera kwa plasma arc ndi njira zina zokhala ndi mphamvu zowonjezera kutentha kwapakati zimatha kugwiritsidwa ntchito.

Pofuna kuchepetsa kuzama kolowera, njira zaumisiri monga indirect arc, swing welding wire, strip electrode, ndi zina zowonjezera zopanda mphamvu zowotcherera zitha kukhazikitsidwa.Koma zivute zitani, bola ngati fusion kuwotcherera, mbali ya chitsulo m'munsi nthawi zonse kusungunuka mu weld ndi kuyambitsa dilution.Komanso, intermetallic mankhwala, eutectics, etc. adzapangidwanso.Kuti muchepetse zovuta zotere, nthawi yokhala zitsulo mumadzimadzi kapena kutentha kwambiri kolimba iyenera kuyendetsedwa ndikufupikitsidwa.

Komabe, ngakhale kuwongolera mosalekeza ndikuwongolera njira zowotcherera ndi njira zowotcherera, zimakhala zovuta kuthetsa mavuto onse pakuwotcherera zitsulo zofananira, chifukwa pali mitundu yambiri yazitsulo, zofunikira zosiyanasiyana zogwirira ntchito, ndi mitundu yosiyanasiyana yolumikizirana.Nthawi zambiri, m'pofunika Kupanikizika kuwotcherera kapena njira zina kuwotcherera ntchito kuthetsa mavuto kuwotcherera enieni dissimilar zitsulo mfundo.

2. Kuwotcherera kwamphamvu

Njira zambiri zowotcherera zokakamiza zimangotenthetsa chitsulo kuti chiwotchedwe ndi pulasitiki kapena musatenthe, koma gwiritsani ntchito kukakamiza kwina monga chinthu chofunikira.Poyerekeza ndi kuwotcherera maphatikizidwe, kuwotcherera kwamphamvu kuli ndi zabwino zina powotcherera mfundo zachitsulo zosiyana.Malingana ngati mawonekedwe ophatikizana amalola ndipo khalidwe la kuwotcherera limatha kukwaniritsa zofunikira, kuwotcherera kukakamiza nthawi zambiri kumakhala koyenera.

Panthawi yowotcherera, mawonekedwe azitsulo zosiyana amatha kusungunuka kapena sangasungunuke.Komabe, chifukwa cha mphamvu ya kupanikizika, ngakhale chitsulo chosungunulidwa pamwamba pake, chidzatulutsidwa ndi kutulutsidwa (monga kuwotcherera kwa flash ndi kuwotcherera).Nthawi zingapo Kamodzi chitsulo chosungunula amakhalabe pambuyo kuthamanga kuwotcherera (monga malo kuwotcherera).

Popeza kuthamanga kuwotcherera sikutenthetsa kapena kutentha kwa kutentha kumakhala kochepa, kumatha kuchepetsa kapena kupewa zotsatira zoyipa za matenthedwe azinthu pazitsulo zazitsulo zam'munsi ndikuletsa kupanga ma brittle intermetallic compounds.Njira zina zowotcherera zokakamiza zimatha kufinyanso ma intermetallic omwe adapangidwa kuchokera pagulu.Komanso, palibe vuto la kusintha katundu wa weld zitsulo chifukwa dilution pa kuthamanga kuwotcherera.

Komabe, njira zambiri zowotcherera zokakamiza zimakhala ndi zofunika zina za mawonekedwe olowa.Mwachitsanzo, kuwotcherera malo, kuwotcherera msoko, ndi kuwotcherera akupanga ayenera kugwiritsa ntchito zolumikizira;pa kuwotcherera mikangano, workpiece imodzi iyenera kukhala ndi gawo lozungulira la thupi;kuwotcherera kuphulika kumangogwiritsidwa ntchito polumikizana ndi malo Aakulu, ndi zina. Zida zowotcherera zokakamiza sizinadziwikebe.Izi mosakayikira zimachepetsa kuchuluka kwa ntchito yowotcherera.

3. Njira zina

Kuphatikiza pa kuwotcherera ma fusion ndi kuwotcherera kuthamanga, pali njira zingapo zomwe zingagwiritsidwe ntchito kuwotcherera zitsulo zosiyana.Mwachitsanzo, kuwotcherera zitsulo zosiyana pakati pa zitsulo zodzaza ndi zitsulo, koma zomwe zikukambidwa apa ndi njira yapadera yowotchera.

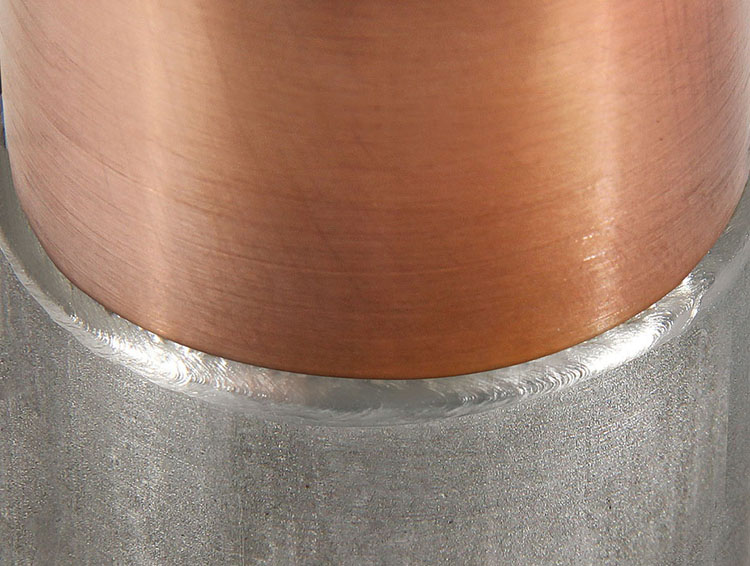

Pali njira yotchedwa fusion welding-brazing, ndiko kuti, mbali yachitsulo yotsika kwambiri yachitsulo chosakanikirana ndi fusion-welded, ndipo mbali yachitsulo yosungunuka kwambiri imakhala yonyezimira.Ndipo nthawi zambiri chitsulo chofanana ndi chotsika chosungunuka chimagwiritsidwa ntchito ngati solder.Chifukwa chake, njira yowotcherera pakati pa chitsulo cha brazing filler ndi chitsulo chotsika chosungunuka ndi chitsulo chomwecho, ndipo palibe zovuta zapadera.

Njira yopangira brazing ili pakati pa chitsulo chodzaza ndi chitsulo chosungunuka kwambiri.Chitsulo choyambira sichisungunuka kapena kusungunula, chomwe chimatha kupewa zovuta zambiri zowotcherera, koma chitsulo chodzaza chimafunika kuti chinyowetse zitsulo zoyambira bwino.

Njira ina imatchedwa eutectic brazing kapena eutectic diffusion brazing.Uku ndikutenthetsa malo okhudzana ndi zitsulo zosagwirizana ndi kutentha kwina, kotero kuti zitsulo ziwirizo zimapanga eutectic yotsika yosungunuka pamalo okhudzana.The otsika kusungunuka mfundo eutectic ndi madzi kutentha uku, makamaka kukhala ngati solder popanda kufunika solder kunja.Njira ya brazing.

Inde, izi zimafuna kupanga eutectic yotsika-kusungunuka pakati pazitsulo ziwirizi.Panthawi yowotcherera zitsulo zosiyana, chinthu chapakati chimawonjezedwa, ndipo chapakati chapakati chimatenthedwa ndi kupanikizika kochepa kwambiri kuti chisungunuke, kapena kupanga malo otsika osungunuka a eutectic pokhudzana ndi zitsulo kuti aziwotcherera.Wowonda wosanjikiza wa madzi anapanga panthawi imeneyi, patapita nthawi ya kutentha kuteteza ndondomeko, zimapangitsa wapakatikati wosanjikiza zakuthupi kusungunuka.Pamene zipangizo zonse zapakatikati zimagawidwa muzitsulo zapansi ndikugwirizanitsa, cholumikizira chachitsulo chosiyana popanda zipangizo zapakatikati chikhoza kupangidwa.

Njira yamtunduwu idzatulutsa chitsulo chochepa chamadzimadzi panthawi yowotcherera.Choncho, amatchedwanso madzi gawo kusintha kuwotcherera.Chodziwika bwino chawo ndikuti palibe mawonekedwe oponyera mu mgwirizano.

Zinthu zomwe muyenera kuzizindikira mukawotchera zitsulo zosiyana

1. Ganizirani zakuthupi, zamakina ndi kapangidwe kake kakawotcherera

(1) Malinga ndi mphamvu yofanana, sankhani ndodo zowotcherera zomwe zimakumana ndi mawotchi azitsulo zam'munsi, kapena kuphatikiza kutsekemera kwazitsulo zam'munsi ndi ndodo zowotcherera ndi mphamvu zopanda mphamvu ndi weldability wabwino, koma ganizirani mawonekedwe a zitsulo. weld kukumana ndi mphamvu zofanana.Mphamvu ndi zofunikira zina zowuma.

(2) Pangani ma alloy ake kuti agwirizane kapena pafupi ndi maziko ake.

(3) Chitsulo choyambira chikakhala ndi zonyansa zambiri za C, S, ndi P, ndodo zowotcherera zokhala ndi kukana bwino kwa ming'alu ndi kukana kwa porosity ziyenera kusankhidwa.Ndi bwino kugwiritsa ntchito kashiamu titaniyamu okusayidi elekitirodi.Ngati sichingathetsedwebe, ndodo yotsika ya haidrojeni ya sodium ingagwiritsidwe ntchito.

2. Ganizirani momwe ntchito ikugwirira ntchito ndi momwe mawotchi amachitira

(1) Pansi pa kunyamula katundu wosunthika ndi katundu wokhudzidwa, kuwonjezera pakuwonetsetsa mphamvu, pali zofunika kwambiri pakulimba kwamphamvu komanso kutalika.Mtundu wa haidrojeni wotsika, mtundu wa titaniyamu wa calcium ndi maelekitirodi amtundu wa iron oxide ayenera kusankhidwa nthawi imodzi.

(2) Ngati kukhudzana ndi zowononga TV, zoyenera zosapanga dzimbiri kuwotcherera ndodo ayenera kusankhidwa potengera mtundu, ndende, ntchito kutentha kwa TV, ndi kaya zovala kapena intergranular dzimbiri.

(3) Pogwira ntchito yovala, ziyenera kuzindikirika ngati ndizovala zachilendo kapena zokhudzidwa, komanso ngati zimavala pa kutentha kwabwino kapena kutentha kwambiri.

(4) Pogwira ntchito mopanda kutentha, ndodo zowotcherera zofananira zomwe zimatsimikizira kuti makina otsika kapena kutentha kwapamwamba ayenera kusankhidwa.

3. Ganizirani zovuta za mawonekedwe ophatikizana a weldment, kuuma, kukonzekera fracture yowotcherera ndi malo otsekemera.

(1) Kwa ma welds okhala ndi mawonekedwe ovuta kapena makulidwe akulu, kupsinjika kwa chitsulo chowotcherera pakuzizira kumakhala kwakukulu ndipo ming'alu imatha kuchitika.Ndodo zowotcherera zokhala ndi ming'alu zolimba ziyenera kusankhidwa, monga ndodo zowotcherera za haidrojeni, ndodo zowotcherera zolimba kwambiri kapena ndodo zowotcherera za iron oxide.

(2) Kwa zowotcherera zomwe sizingatembenuzidwe chifukwa cha mikhalidwe, ndodo zowotcherera zomwe zimatha kuwotcherera m'malo onse ziyenera kusankhidwa.

(3) Pazigawo zowotcherera zomwe zimakhala zovuta kuyeretsa, gwiritsani ntchito ndodo zowotcherera acidic zomwe zimakhala ndi okosijeni komanso zosakhudzidwa ndi sikelo ndi mafuta kuti mupewe zolakwika monga pores.

4. Ganizirani zida zowotcherera malo

Kumalo komwe kulibe makina owotcherera a DC, sikoyenera kugwiritsa ntchito ndodo zowotcherera zokhala ndi magetsi ochepa a DC.M'malo mwake, ndodo zowotcherera zokhala ndi magetsi a AC ndi DC ziyenera kugwiritsidwa ntchito.Zitsulo zina (monga chitsulo chosagwira kutentha kwa pearlitic) zimayenera kuthetsa kupsinjika kwa kutentha pambuyo pa kuwotcherera, koma sizingatenthedwe chifukwa cha zida (kapena zoperewera zamapangidwe).Ndodo zowotcherera zopangidwa ndi zitsulo zopanda maziko (monga zitsulo zosapanga dzimbiri za austenitic) ziyenera kugwiritsidwa ntchito m'malo mwake, ndipo chithandizo cha kutentha pambuyo pa weld sikofunikira.

5. Ganizirani kukonza njira zowotcherera ndi kuteteza thanzi la ogwira ntchito

Kumene ma electrodi a asidi ndi amchere amatha kukwaniritsa zofunikira, ma elekitirodi a asidi ayenera kugwiritsidwa ntchito momwe angathere.

6. Ganizirani zokolola za anthu ogwira ntchito komanso kulingalira bwino kwachuma

Pankhani ya ntchito yomweyi, tiyese kugwiritsa ntchito ndodo zowotcherera za acidic zotsika mtengo m'malo mwa ndodo zowotcherera zamchere.Pakati pa ndodo zowotcherera acidic, mtundu wa titaniyamu ndi mtundu wa titaniyamu-kashiamu ndizokwera mtengo kwambiri.Malinga ndi momwe chuma cha dziko langa chilili, chitsulo cha titaniyamu chiyenera kukwezedwa mwamphamvu.Zokutidwa kuwotcherera ndodo.

Nthawi yotumiza: Oct-27-2023