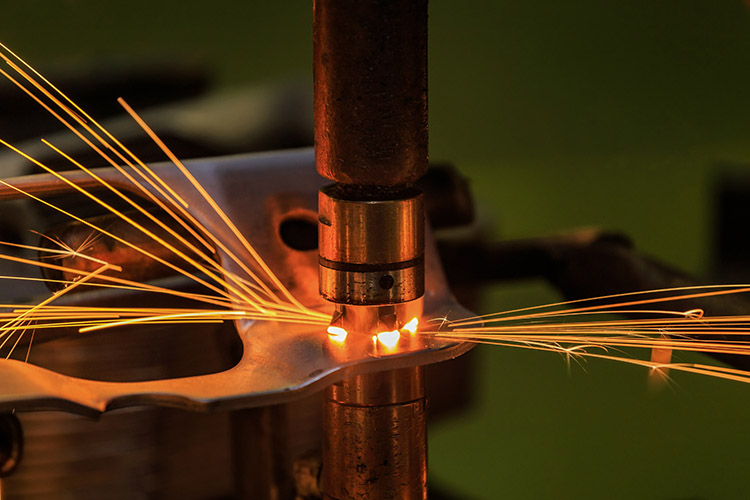

Spot kuwotcherera ndi kukana kuwotcherera njira imene kuwotcherera amasonkhanitsidwa mu chilolo olowa ndi mbamuikha pakati maelekitirodi awiri, ndi m'munsi zitsulo amasungunuka ndi kukana kutentha kupanga solder olowa.

Spot kuwotcherera kumagwiritsidwa ntchito makamaka pazinthu izi:

1. Chigawo cholumikizira mapepala, monga cab yamagalimoto, chonyamulira, chotchingira nsomba, ndi zina zambiri.

2. Zitsulo zopyapyala ndi zigawo zazitsulo ndi zikopa zapakhungu, monga makoma am'mbali ndi denga la zotengera, mapanelo a chipinda cha trailer, kuphatikiza ma funnels, ndi zina zambiri.

3. Zowonetsera, mafelemu a danga ndi mipiringidzo, ndi zina zotero.

Cwovutitsa

Pa kuwotcherera malo, kuwotchererako kumapanga cholumikizira cha lap ndipo amapanikizidwa pakati pa ma elekitirodi awiri.Makhalidwe ake akuluakulu ndi awa:

1. Nthawi yotentha ya malo olumikizirana ndi yochepa kwambiri pakuwotcherera malo, ndipo liwiro la kuwotcherera limathamanga.

2. Spot kuwotcherera kumangodya mphamvu yamagetsi, ndipo sikufuna zinthu zodzaza kapena kutulutsa, gasi, ndi zina zotero.

3. Ubwino wa kuwotcherera malo amatsimikiziridwa ndi malo kuwotcherera makina.Opaleshoniyo ndi yophweka, mlingo wa makina ndi automation ndi wokwera, ndipo zokolola ndizokwera.

4. Kuchepa kwa ntchito komanso malo abwino ogwirira ntchito.

5. Popeza kuti kuwotcherera mphamvu kumatsirizidwa mu nthawi yochepa, mphamvu yaikulu yamakono ndi kupanikizika kumafunika, kotero kuti ndondomeko yoyendetsera ndondomekoyi imakhala yovuta kwambiri, makina opangira zitsulo ali ndi mphamvu zambiri, ndipo mtengo wa zipangizozo ndi wofanana. apamwamba.

6.Ndizovuta kuyesa kuyesa kosawononga pazitsulo za solder.

Ntchito ndondomeko

Pamwamba pa workpiece ayenera kutsukidwa pamaso kuwotcherera.Njira yoyeretsera yomwe imagwiritsidwa ntchito kwambiri ndikutsuka, ndiko kuti, kukhetsa mu kutentha kwa sulfuric acid ndi 10%, ndikutsuka m'madzi otentha.Mwachindunji kuwotcherera ndondomeko ndi motere:

(1) Tumizani workpiece olowa pakati chapamwamba ndi m'munsi maelekitirodi a malo kuwotcherera makina ndi achepetsa izo;

(2) magetsi, kotero kuti malo okhudzana ndi ntchito ziwirizo amatenthedwa ndikusungunuka pang'ono kuti apange nugget;

(3) Sungani kupanikizika pambuyo pa kudulidwa mphamvu, kotero kuti nugget itakhazikika ndikukhazikika pansi pa kukakamizidwa kuti apange mgwirizano wa solder;

(4) Chotsani kukakamiza ndikuchotsa chogwirira ntchito.

Zinthu zosonkhezera

Zinthu zazikulu zomwe zimakhudza kuwotcherera kwamtundu ndi nthawi yowotcherera pano komanso nthawi yopatsa mphamvu, kuthamanga kwa electrode ndi shunt, etc.

1. Kuwotcherera panopa ndi nthawi nyonga

Malinga ndi kukula kwa kuwotcherera pakali pano komanso kutalika kwa nthawi yopangira mphamvu, kuwotcherera kwa malo kumatha kugawidwa m'mitundu iwiri: mawonekedwe olimba komanso mawonekedwe ofewa.Kufotokozera komwe kumadutsa mphamvu yayikulu mu nthawi yochepa kumatchedwa hard specification.Zili ndi ubwino wa zokolola zambiri, moyo wautali wa elekitirodi, ndi mapindikidwe ang'onoang'ono a weldment.Ndi oyenera kuwotcherera zitsulo ndi matenthedwe bwino matenthedwe madutsidwe.Chidziwitso chomwe chimadutsa kamphindi kakang'ono kwa nthawi yayitali chimatchedwa ndondomeko yofewa, yomwe imakhala ndi zokolola zochepa ndipo ndi yoyenera zitsulo zowotcherera zomwe zimakhala zolimba.

2. Kuthamanga kwa Electrode

Pa kuwotcherera malo, kupanikizika komwe kumachitika ndi electrode pa weldment kumatchedwa electrode pressure.Kuthamanga kwa electrode kuyenera kusankhidwa moyenera.Pamene kupanikizika kuli kwakukulu, shrinkage porosity ndi shrinkage cavity yomwe ingathe kuchitika pamene nugget imalimba imatha kuthetsedwa, koma kukana kwa kugwirizana ndi kuchepa kwamakono kumachepa, zomwe zimapangitsa kutentha kosakwanira kwa weldment ndi kuchepa kwapakati pa nugget ya nugget. mgwirizano wa solder.Mphamvu ya mgwirizano wa solder imachepetsedwa.Kukula kwa kuthamanga kwa electrode kumatha kusankhidwa malinga ndi izi:

(1) Zida zowotcherera.The apamwamba kutentha mphamvu zakuthupi.Kuthamanga kwakukulu kwa electrode kumafunika.Choncho, pamene kuwotcherera zitsulo zosapanga dzimbiri ndi zitsulo zosagwira kutentha, mphamvu ya elekitirodi iyenera kukhala yapamwamba kuposa yachitsulo chochepa cha carbon.

(2) Zowotcherera magawo.Kuchulukirachulukira kwa weld, kumapangitsanso mphamvu ya electrode.

3. kuseka

Pa kuwotcherera malo, magetsi akuyenda kuchokera kunja kwa gawo lalikulu la kuwotcherera amatchedwa shunt.The shunt amachepetsa panopa akuyenda m'dera kuwotcherera, kuchititsa kutentha osakwanira, kuchititsa kuchepa kwambiri mphamvu ya solder olowa ndi kukhudza kuwotcherera khalidwe.Zinthu zomwe zimakhudza kuchuluka kwa kusokoneza makamaka zimaphatikizapo izi:

(1) Kunenepa kwa chowotcherera ndi kutalikirana kwa malo olumikizirana zitsulo.Pamene mtunda pakati pa ma solder akuwonjezeka, kukana kwa shunt kumawonjezeka ndipo mlingo wa shunt umachepa.Pamene madontho ochiritsira a 30-50mm atengedwa, shunt panopa amawerengera 25% -40% ya chiwerengero chamakono, ndipo pamene makulidwe a weldment amachepetsa, mlingo wa shunt umachepanso.

(2) Mkhalidwe wapamtunda wa weld.Pakakhala ma oxides kapena dothi pamwamba pa kuwotcherera, kukana kukhudzana pakati pa ma welds awiri kumawonjezeka, ndipo pano kudzera m'dera lakuwotcherera kumachepa, ndiko kuti, kuchuluka kwa shunt kumawonjezeka.Chogwirira ntchitocho chikhoza kudulidwa, sandblasted kapena kupukutidwa.

Chitetezo

(1) Kusintha kwa phazi la makina owotcherera kuyenera kukhala ndi chivundikiro cholimba choteteza kuti chiteteze mwangozi.

(2) Malo ogwirira ntchito azikhala ndi chotchinga kuti ateteze kuphulika kwa zipsera zogwira ntchito.

(3) Owotchera ayenera kuvala magalasi oteteza athyathyathya powotchera.

(4) Malo omwe makina owotcherera amayikidwa ayenera kukhala owuma, ndipo pansi payenera kuphimbidwa ndi matabwa otsutsa-skid.

(5) Pambuyo pa ntchito yowotcherera, magetsi ayenera kudulidwa, ndipo chosinthira madzi ozizira chiyenera kuwonjezeredwa kwa masekondi 10 musanatseke.Kutentha kukakhala kotsika, madzi owunjikana munjira yamadzi ayenera kuchotsedwa kuti asaundane.

Nthawi yotumiza: Jul-31-2023