Ndi chiyanikuwotcherera kwa arc flux-cored?

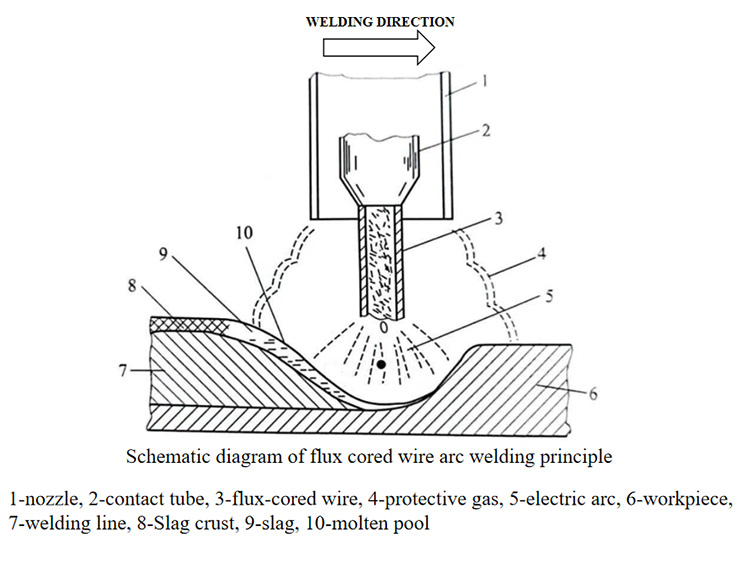

Flux-cored wire arc welding ndi njira yowotcherera yomwe imagwiritsa ntchito arc pakati pa waya wa flux-cored ndi workpiece kuti itenthetse, ndipo dzina lake la Chingerezi ndi FCAW chabe.Pansi pa kutentha kwa arc, zitsulo zowotcherera waya ndi workpiece zimagwirizanitsidwa ndi kusungunuka, kupanga dziwe la weld, arc patsogolo pambuyo pa crystallization ya weld pool mchira.

Kodi waya wa flux-cored ndi chiyani?Kodi mawonekedwe a cartridge ndi ati?

Waya wowotcherera wa Flux-cored ndi mtundu wa waya wowotcherera wopangidwa ndikugudubuza chingwe chopyapyala chachitsulo mu chitoliro chachitsulo kapena chitoliro chachitsulo chopangidwa mwapadera, kudzaza chitoliro ndi zigawo zina za ufa, ndi kujambula.The zikuchokera pachimake ufa ndi ofanana ndi ❖ kuyanika elekitirodi, amene makamaka wapangidwa ndi arc stabilizing wothandizila slag kupanga wothandizila, mpweya kupanga wothandizila, alloying wothandizila, deoxidizing wothandizira, etc.

Kodi gawo la flux mu waya wa flux-cored ndi chiyani?

Udindo wa flux ndi wofanana ndi wa zokutira ma elekitirodi, ndipo pali makamaka mitundu yotsatirayi.

① Kuteteza kwa zigawo zina pakuwotchera kwa flux, kusungunuka kwina!Kuwonongeka kwa kuwotcherera kumatulutsa mpweya, womwe umapereka chitetezo china kapena chochuluka.Kusungunuka kosungunuka kumapanga slag yosungunuka, yomwe imaphimba pamwamba pa dontho ndi dziwe losungunuka, ndipo zitsulo zamadzimadzi zimatetezera.

② Arc stabilizer mu arc stabilizer cartridge imatha kukhazikika arc ndikuchepetsa kuchuluka kwa spatter.

③ Kuchita kwa alloying Zinthu zina za alloy pachimake zimatha kutulutsa chowotcherera.

④ Deoxidation alloy alloy of slag amatha kuchitapo kanthu ndi zitsulo zamadzimadzi.Sinthani kapangidwe ka weld zitsulo, kusintha makina ake.

Kuonjezera apo, slag yokutidwa ingathenso kuchepetsa kuzizira kwa dziwe losungunuka, kutalikitsa kukhalapo kwa dziwe losungunuka, lomwe limapindulitsa kuchepetsa zomwe zili ndi mpweya woipa mu weld ndikuletsa porosity.

Ndi mitundu yanji ya kuwotcherera arc cored flux yomwe ilipo?

Pali mitundu iwiri ya flux cored wire arc welding (FCAW-G) ndi self-protection welding (FCAW-S), kutengera ngati gasi wotchinga wakunja amagwiritsidwa ntchito kapena ayi.

Mawotchi otetezedwa ndi mpweya wa waya wa flux-cored nthawi zambiri amagwiritsa ntchito mpweya woipa kapena carbon dioxide kuphatikiza argon ngati mpweya wotchinga, ndipo kutulutsa kwa waya kumakhala ndi mpweya wochepa.Njirayi ndi yofanana ndi kuwotcherera komwe kumatetezedwa ndi gasi.Kuwotcherera kudziteteza sikufuna mpweya woteteza kunja.Pali kuchuluka kwa gasifier mu flux, ndipo gasi ndi slag zowola ndi gasifier zimagwiritsidwa ntchito poteteza.

Ubwino wowotcherera arc flux-cored ndi chiyani?

Flux-cored arc welding ili ndi izi zabwino.

(1) High kuwotcherera zokolola mkulu kusungunuka dzuwa (mpaka 85% ~ 90%), mofulumira kusungunuka;Pa kuwotcherera lathyathyathya, liwiro ❖ kuyanika ndi 1.5 kuwirikiza 1.5 kuposa kuwotcherera arc pamanja, ndi malo ena kuwotcherera, ndi kuwirikiza 3-5 kuposa kuwotcherera pamanja.

② Kuwala kwakung'ono, kuwotcherera kumapanga mankhwala abwino kwambiri owonjezera arc stabilizer, kukhazikika kwa arc, kuwotcherera pang'ono, kupanga weld wabwino.Chifukwa dziwe losungunukalo limakutidwa ndi slag wosungunuka, mawonekedwe a weld pamwamba ndi abwino kwambiri kuposa a carbon dioxide welding.

(3) Kuwotcherera kwapamwamba Chifukwa cha chitetezo chophatikizana ndi gasi la slag, chingathe kuteteza bwino mpweya woipa kuti usalowe m'madera otsekemera.Kuphatikiza apo, nthawi yokhalapo kwa dziwe losungunuka ndi yayitali, yomwe imathandizira kugwa kwa mpweya, kotero kuti weld imakhala ndi haidrojeni yochepa komanso kukana bwino kwa porosity.

(4) Kusinthasintha kwamphamvu kumangofunika kusintha mawonekedwe a waya wa solder, amatha kukwaniritsa zofunikira zazitsulo zosiyanasiyana pakupanga.

Kodi kuipa kwake kowotcherera arc flux-cored ndi chiyani?

Zofooka za flux-cored arc welding ndi izi.

Poyerekeza ndi kuwotcherera kwa gasi wotetezedwa, mtengo wa waya wowotcherera ndi wapamwamba ndipo njira yopangira ndi yovuta.

② Kudyetsa mawaya ndikovuta, ndikofunikira kugwiritsa ntchito makina odyetsera mawaya omwe kuthamanga kwake kungathe kusinthidwa molondola.

③ Katiriji ndiyosavuta kuyamwa chinyezi, kotero ndikofunikira kusunga waya wowotcherera mosamalitsa.

④ Kuchotsa slag kumafunika pambuyo kuwotcherera.

⑤ Utsi wochuluka ndi mpweya woipa umapangidwa powotcherera, motero mpweya wabwino uyenera kulimbikitsidwa.

Ndi mpweya wotani woteteza womwe nthawi zambiri umagwiritsidwa ntchito powotcherera arc cored?Kodi aliyense ali ndi makhalidwe otani?

Flux cored wire arc welding nthawi zambiri amagwiritsa ntchito mpweya wabwino wa carbon dioxide kapena carbon dioxide ndi mpweya wa argon ngati mpweya wotetezera.Mtundu wa gasi uyenera kusankhidwa molingana ndi waya wa flux-cored wogwiritsidwa ntchito.

Argon ndi ionized mosavuta, kotero ndikosavuta kukwaniritsa kusintha kwa ejection mu argon arc.Pamene argon zili mpweya osakaniza ndi zosachepera 75%, ndi flux cored waya arc kuwotcherera akhoza kukwaniritsa khola ndege kusintha.Ndi kuchepa kwa zinthu za argon, kuya kwa kulowa kumawonjezeka, koma kukhazikika kwa arc kumachepa ndipo kuchuluka kwa spatter kumawonjezeka.Choncho, mulingo woyenera mpweya osakaniza ndi 75% Ar + 25% CO2.Kuphatikiza apo, Ar + 2% O2 itha kugwiritsidwanso ntchito posakaniza gasi.

Mpweya wa CO2 ukasankhidwa, umawonongeka chifukwa cha kutentha kwa arc ndikupanga maatomu ambiri a okosijeni, omwe amathira manganese, silicon ndi zinthu zina mu dziwe losungunuka, zomwe zimatsogolera pakuwotcha kwa zinthu za alloying.Chifukwa chake, waya wowotcherera wokhala ndi manganese ambiri ndi silicon ayenera kugwiritsidwa ntchito.

Nthawi yotumiza: May-09-2023